ALL SYSTEMS

ALL PACKAGES

ALL PRODUCTS

ALL SYSTEMS

ALL PACKAGES

ALL PRODUCTS

We are a company with an extensive and in deep experience in canned and frozen foods within the food industry sector. The founding of the company dates back to the year 1969.Our first steps towards the development and establishment of machinery for the canned food sector soon proved to be a leading competitive factor, which led to an exponential growth in production, therefore establishing a new work philosophy centered on investigation research and development.

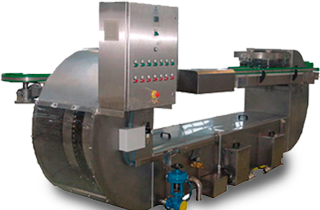

Washers series

Different available options designed to wash containers, vegetables, product in process, rotary washing machine,

box washing machine.

The equipment’s are manufactured of stainless steel and other noncorrosive elements.

Piston Filler

The machine is suitable for the volumetric filling of dense products such as marmalades, peeled tomatoes, diced tomatoes, etc., always in rigid containers (jar or can).

Synchronized containers feeding to the filler’s valves.

System of fast assembly and dissembling of the valves pistons for its fast and easy cleaning.

Volumetric Filler

This type of machine bases its product filling system on a rotational system on its feeding stars and exit using telescopic containers. These are completely adjustable depending on the format being used. Completely homogeneous filling is achieved in all containers.

Cookers- Blancher

Built entirely out of stainless steel. Joint pump in the water circuit to homogenize the warm water. Indirect water heating. Automatic temperature control. Adjustable speed. Manufactured in different capacities in accordance with the clients requirements.

Rotative solid eliminator

Capacity of filtering up to 120 cubic meters per hour, with a mesh light of 0.5 mm. Built entirely out of stainless steel, with closing covers in transparent polycarbonate. Interior cleaning of the filtering cylinder.

Balls of concentrate

Built entirely out of stainless steel. Consisting of: Ball of concentrate, embossed band, cupola, shaker and sample taking device, observation peepholes, vacuum breaker taps, vacuum gauge, security valve, purge-cock and product discharge valve. Condenser with a flotation valve which automatically regulates the water level. Electro-pump group: for extraction of condensation water. Electro-pump group for application of the vacuum. Main deposit to support the load of the ball. Structure: to support all the eliminated elements.

Tray pallet loaders

Its function is the automatic gathering and grouping of shrink-wrapped trays or boxes, for their subsequent stacking on pallets in an organized manner.

Each layer allows for the shaping of different types of mosaic.